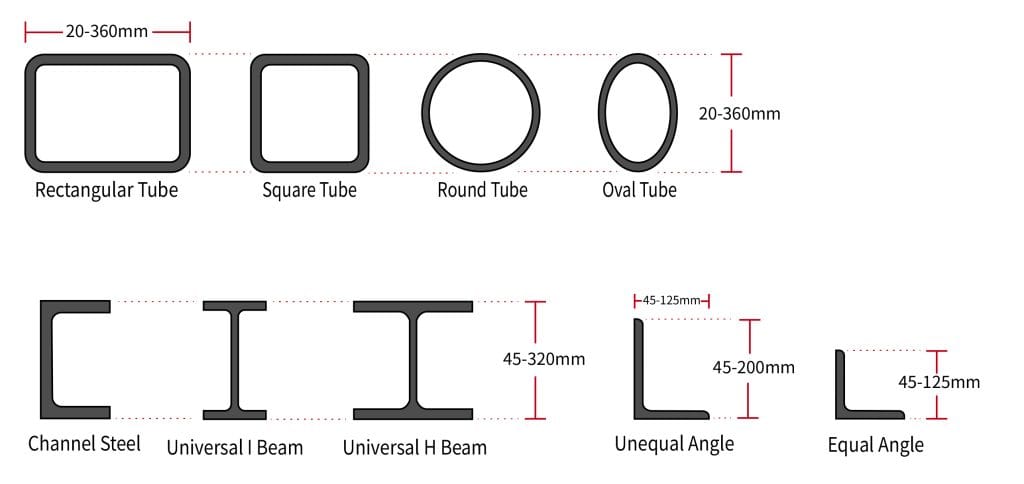

At Fabronex, we bring your complex designs to life with advanced tube laser cutting technology that delivers unmatched precision, speed, and versatility. Whether you’re cutting round, square, or rectangular tubes, y

channels (PFC), or universal H-beams and I-beams, our state-of-the-art 3D 5-axis machines ensure clean, accurate cuts every time.

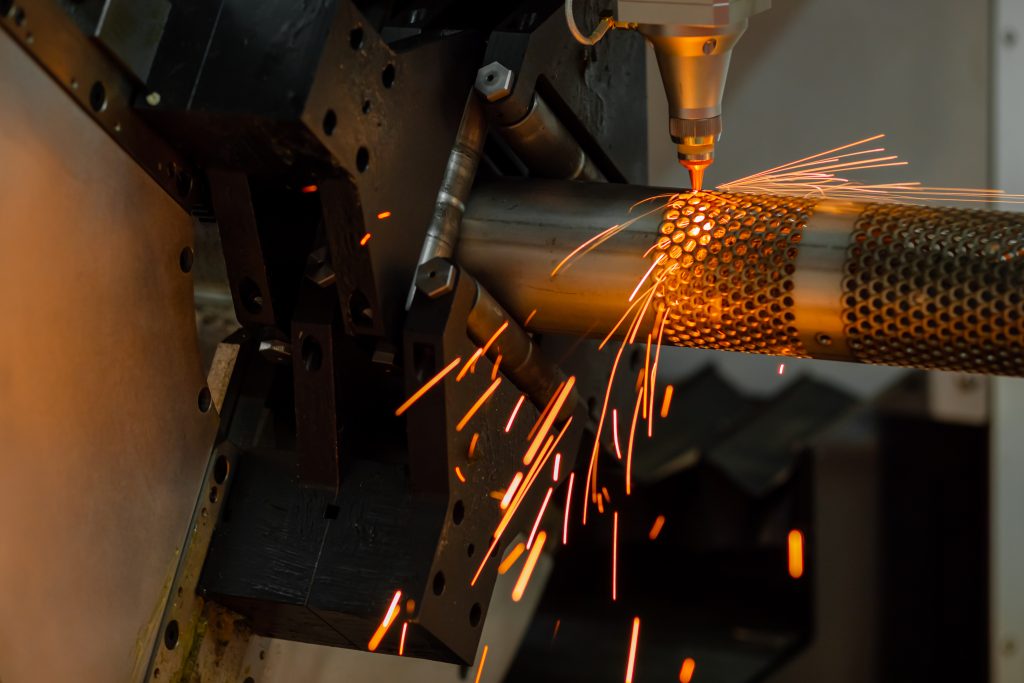

Using 3D cutting-edge tube laser systems include bevel cutting for weld fit up , we process tubes up to Ø350mm in diameter and 20mm in wall thickness, accommodating a wide range of heavy-duty and structural applications.

Our system features automated loading and unloading for tubes up to 12 meters in length — well beyond the industry standard — allowing us to handle long sections with exceptional speed, precision, and minimal manual intervention.

Whether you’re prototyping a new part or ramping up to full production, Fabronex delivers precise, repeatable results with tight tolerances and minimal post-processing even on large-format jobs.

From structural to decorative components, our 5-axis cutting systems allow for complex geometries, bevel cuts up to 45 degrees, angled cuts, slots, notches, and custom features, all performed with precision across a full range of materials, including galvanized steel, stainless steel, mild steel, aluminum, and carbon steel.

We specialize in cutting all types of Pipes, Structural Beams (H Beams & I Beams), RHS, SHS, PFC, Angles, and any other custom shapes. These services are available for materials such as Mild Steel, Stainless Steel, Aluminium, and more. We achieve this with precision, high accuracy, and high quality, ensuring maximum planning and design flexibility. When we cut a 777mm tube, it’s exactly 777mm, with flawless repeatability.

Materials Type |

Max Thickness (mm) |

|---|---|

Mild Steel | 20 |

Stainless Steel | 14 |

Aluminum | 12 |

Galvanized Steel | 12 |

Brass | 10 |

Copper | 8 |

Fabronex delivers precision-engineered metal components through advanced tube laser cutting, sheet metal processing, and fabrication technologies. From prototyping to full-scale production, we ensure speed, accuracy, and reliability.